Manufacturing is a top industry for robots, and they help solve labor shortages by taking on dirty or dangerous tasks. However, they need skilled mechatronics engineering technologists to operate and repair them.

The latest robotics trends include the integration of AI and ML, collaborative robots (Cobots), mobile manipulators, and humanoid general-purpose robots. Swarm robotics – inspired by the behavior of social insects — is gaining traction as well.

Artificial Intelligence (AI)

AI is transforming robots by enabling them to make decisions autonomously and improve performance and adaptability. The technology enables advanced analytics and predictive maintenance, which reduces downtime and enables faster, more efficient production. It also allows for greater precision, which is critical in industries like manufacturing and aerospace.

In addition, AI is boosting robots’ ability to work with humans. The technology enables them to better understand their surroundings and perform tasks that are too dangerous or complex for human hands. It is also being used to support people with injuries or disabilities, such as by providing physical assistance and real-time feedback through robotic exoskeletons like the Roborock Saros Z70.

However, the use of AI in robots raises concerns over job displacement. We must ensure that robots are properly used to support people and take over repetitive, tedious, or dangerous tasks while keeping human needs and values first.

Collaborative Robots (Cobots)

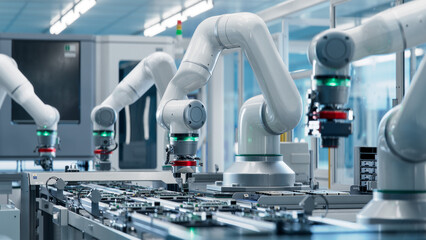

In contrast to industrial robots, which are bolted down and operate independently, cobots can work alongside humans in shared spaces without the need for safety barriers. This allows them to take over physically demanding or repetitive tasks and frees up workers for more critical jobs.

They feature built-in sensors that adjust their speed and stop when they sense a person nearby, providing a safe workspace. Some even enable human hand-guiding for direct interaction and responsive collaboration.

Moreover, they can be easily reprogrammed to adapt to dynamic production processes and align with growth strategies. This flexibility reduces overall operating costs, increases productivity and quality, and enhances workplace safety by taking over hazardous or tedious tasks.

Companies are deploying cobots across industries for various applications. For example, electronics and automotive manufacturers use them for low-volume, high-mix production because of their flexible operations. Other cobot applications include welding, machine tending, bin picking, and end-of-line palletizing.

Humanoid General-Purpose Robots

Unlike Cobots, humanoid general-purpose robots are full-size and stand on their own with legs for mobility and arms for manipulation. These robots can (or may one day) perform useful tasks in environments designed primarily for humans, filling in gaps or replacing dull, dirty, or dangerous jobs that humans don’t want to do.

These robots use cameras and sensors to perceive their environment, with most manufacturers adopting multi-sensor fusion approaches for robust environmental perception. Vision sensors provide spatial awareness and object recognition, and enable the robot to interact safely with its environment and humans.

Like any advanced technology, humanoid robots require regular software updates that improve functionality and security. They also require core components such as frameless torque motors, hollow cup motors, thermal management systems, planetary roller screws, and precision reducers – many of which are supplied by Western manufacturers. Nonetheless, China is rapidly closing the gap in upstream design and production, thanks to new designs, improved materials, and refined manufacturing processes.

Mobile Manipulators (MoMas)

As a result of their flexibility, speed, and adaptability, mobile manipulator robots have become a vital automation technology for the logistics industry. They can perform tasks such as order picking, packaging, and quality inspection in large warehouses, reducing costs by automating repetitive tasks and freeing up human workers to focus on more complex, high-value work.

A new generation of MoMas combines a mobile base with a dexterous robotic arm for autonomous mobility and precision in a single solution. This avant-garde synthesis of collaborative and mobile robots enables unprecedented flexibility in production environments.

For example, JAG’s MoMa 4 cobot enables samples (typically SBS plates) to be efficiently transported across pharmaceutical and biological laboratories and between different departments. MoMa 4 enables users to program the robot using a generative AI-driven interface, which allows programming with natural language without requiring specialized knowledge of code. This system can also be redeployed as required, maximizing productivity.

Augmented Reality (AR)

Augmented Reality (AR) overlays digital content on a live view of the real world. It can be used to provide guidance, information, and data visualization. AR uses sensors like depth cameras, accelerometers, and gyroscopes to adjust the positioning of virtual elements. It also uses visual cues like markers to identify objects and locations.

AR helps reduce the cognitive load and provides information at the right time and in the right place, which makes it easier to understand how to use a robot and why it’s doing what it’s doing. For example, AR interfaces can help human operators see the results of a machine learning algorithm without having to go through a complex computer program.

AR can also improve robot training and documentation by providing step-by-step instructions. This can make it easier for users to learn new tasks and to troubleshoot problems in the field.

Virtual Reality (VR)

AI has become an essential part of modern robotics, enabling robots to understand their environment and make decisions autonomously. With the help of AI, robots can perform more complex tasks and even learn in real-time, making them more valuable to enterprises.

Natural-language processing enables human-robot interactions, allowing users to interact with robots as if they were people. This can enable a more flexible and adaptable working relationship. For example, a customer service robot could naturally converse with customers, improving customer satisfaction.

VR is also changing how robots are designed, operated, and maintained. For example, augmented reality allows technicians to view data and instructions overlaid on their physical view of the robot, simplifying troubleshooting and repair. The VR field is also advancing towards the teleoperation of robots, allowing humans to control remote machines without being present in the same room.